Sheet metal products

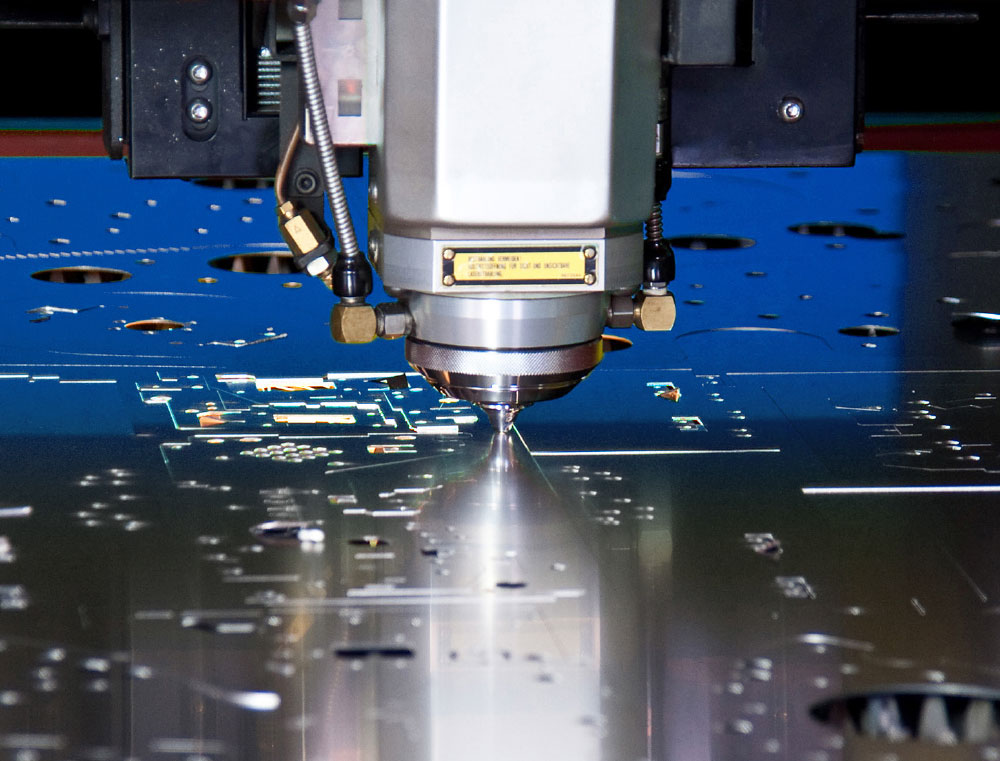

As early as 2015, the first laser cutting system with fiber technology was put into operation at GREIPL Group at ist Röhrnbach facility, at that time still under the name Dittrich & Greipl. Since solid-state laser technology offers enormous performance advantages especially in the thin sheet metal area, gradually more investments in this technology followed. In 2020 the production facilities were moved to the new location Haus im Wald Plant II.

Thus every customer wish is met in the workable material range as well. Besides all the usual metals and alloys, we also process difficult-to-cut metals such as brass, copper or titanium.

High productivity in the area of cutting also makes cost-optimized production of series quantities possible. Where once in the unit cost view only the use of expensive progressive tools was possible, modern CNC technology now offers real alternatives with automated or semi-automated bending technology – even with considerable advantages in flexibility, e.g. in case of part changes.

Of course we also offer all common welding processes as well as connection and joining technologies.

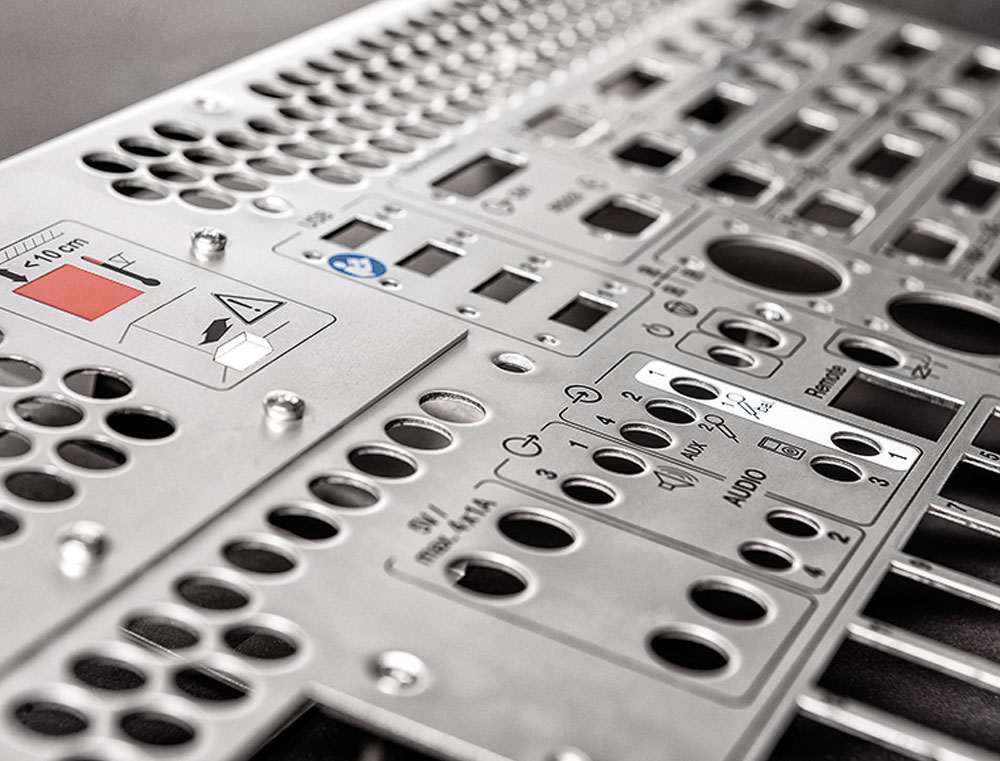

Complete range all the way to printing

We pay special attention to our surface and label range. Our in-house spectrum ranges from parts cleaning through passivation (aluminum and stainless steel via separate procedures) to powder coating. In addition, we have our own screen and pad printing machines.

Apart from that we offer, together with our qualified suppliers, many other surface methods such as glass bead blasting, galvanizing, anodic coating, cathodic dip painting (CDP), wet coating and many more.

The individual requirements of your product are always the decisive factor for the determination of the suitable production process. For us, quality begins already in the planning stage.